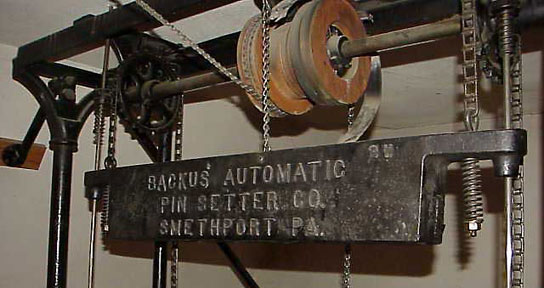

Lee Ritenour Smoke N Mirrors Rarlab more. Rake/Sweep Bar – removes fallen and leftover pins from the pin deck area of the lane.Common part descriptions for just about all pinspotting units consist of: Several types of bowling make use of different designs for machines due to the different size and shape of the pins and balls. Common terms and design features The design of the machines varies, depending both in individual company's hardware designs, and for the particular bowling sport's playing rules and equipment specifications.While many pinsetters have a manual reset button to use in case the pinsetter does not automatically activate at the correct time, other types have no automatic tracking of the state of the game – especially for the and bowling sports which use smaller balls – and are almost always manually activated. Identify the pinsetter number and model type, including the chassis type installed (if present) to be interfaced with the scoring system. Many mechanical pinsetters are integrated with electronic scoring systems of varying sophistication. While humans usually no longer set the pins, a pinchaser, or in slang 'pin monkey', often is stationed near the equipment to ensure that it is clean and working properly, and to clear minor jams. Gottfried (Fred) Schmidt invented the mechanical pinsetter and sold the patent in 1941 to firm, which largely did away with pinsetting as a manual profession, although a small number of bowling alleys still use human pinsetters. Probably due to the nature of the work (low-paid, often part-time, manual labor that most frequently took place evenings), many pinsetters were teenage boys, and thus pinboy is another name used to describe the job. In, a pinsetter, or pinspotter, was originally a person who manually reset to their correct position, cleared fallen pins, and returned to players. I suggested that, with only 8 lanes, he could get by with just the two "safe" hand cranks and just throw out the one I used.Brunswick Model A pinsetter diagram from US patent 2973204. Over to the ER for X-rays which were negative, then back to work for a lecture from the boss on safety. POW! The motor starts up (of course the motor runs much faster than you can crank by hand) and in a couple of seconds it spins the crank (that I left in the machine) such that it smashes into my knee about six times. I put the crank in and cranked the table back up and pushed the reset button on the motor. I happened to grab the one without the disk one night and forgot to remove the power cable.

Two had a large flat disk on the shaft to ensure that you couldn't insert the crank unless you removed the power cable as the disk would obstruct the connector where the cable plugged in.

There was an electric motor with a hole to insert a hand crank in case something went wrong (breaker tripped, jam, etc.). I don't remember if it was an AMF, but I had to futz with the pinspotters when I worked in the rec center in college.

0 kommentar(er)

0 kommentar(er)